Safe, Efficient, and Tailored to Your Needs

Innovative Tekla Structures Solutions

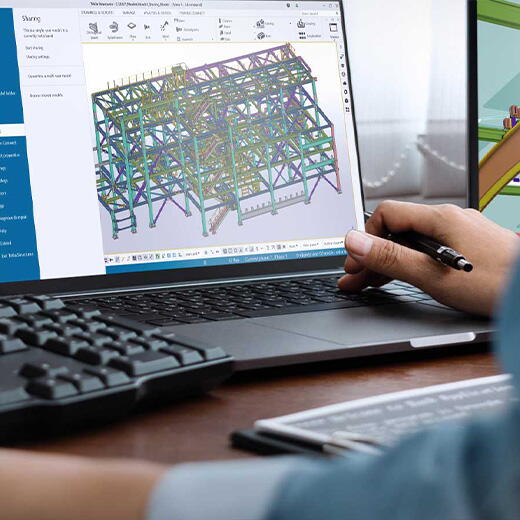

At Static Pro Engineering, we specialize in using Tekla Structures, one of the world’s most advanced software solutions for Building Information Modeling (BIM). Tekla Structures allows engineers, designers, and fabricators to create highly accurate 3D models of steel, concrete, and composite structures with an unparalleled level of detail.

Unlike traditional 2D drafting, Tekla Structures provides a fully integrated modeling environment that covers the entire project lifecycle—from conceptual design and detailing to fabrication and construction. This approach reduces errors, improves collaboration, and ensures seamless coordination across all project stakeholders.

“At Static Pro Engineering, we specialize in providing cutting-edge pressure vessel design solutions. Our mission is to combine innovation, safety, and precision engineering to deliver designs that meet international standards and exceed client expectations. From concept to completion, we ensure every pressure vessel is optimized for performance, durability, and safety.”

Introduction to Tekla Structure

“Pressure vessels are containers designed to hold gases or liquids at high pressure. They are crucial in industries such as chemical processing, oil & gas, power generation, and pharmaceuticals. Proper design is critical to ensure safety, prevent leaks, and maximize efficiency. At Static Pro Engineering, we design pressure vessels that meet rigorous safety standards and operational requirements.

Types of Tekla Structures

Tekla Structures is highly versatile and can be adapted to different types of projects across industries. The main applications include:

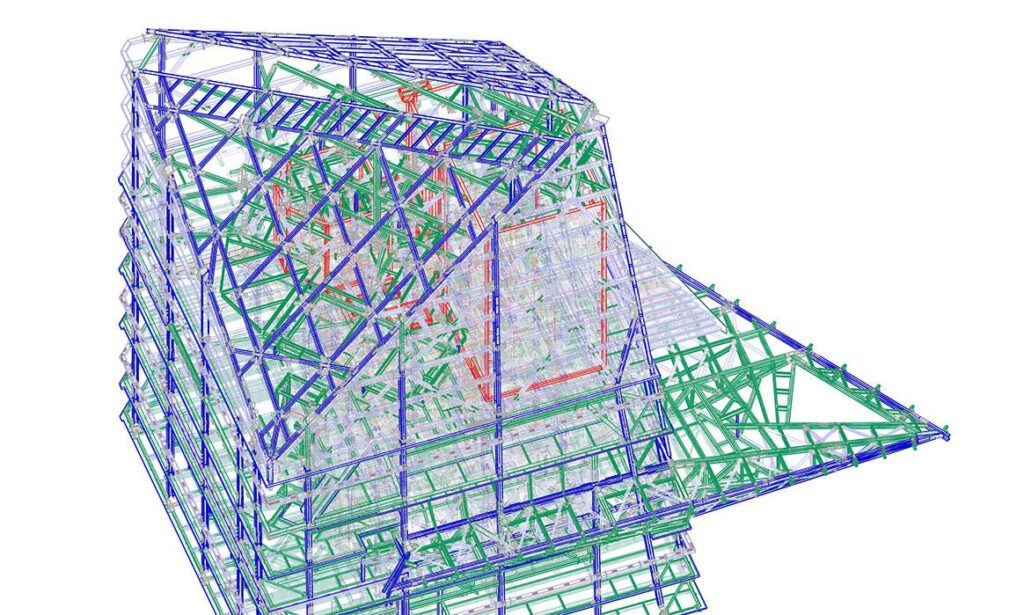

Steel Detailing Models – For creating accurate connections, welds, and fabrication-ready details in steel structures.

Concrete Detailing Models – Used to model reinforcement bars (rebar), precast elements, and cast-in-place concrete structures.

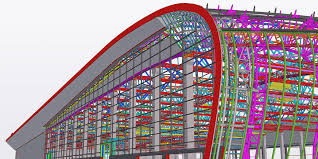

Industrial Plant Models – Specialized designs for oil & gas, power plants, and heavy industries where complex structures are involved.

Bridge & Infrastructure Models – For roadways, bridges, and transport infrastructure requiring precise geometry and reinforcement detailing.

High-Rise & Commercial Models – Detailed BIM for skyscrapers, shopping centers, and office buildings.

Modular & Prefabrication Models – Used to design modular systems for faster construction and cost savings.

Comprehensive Tekla Structures

At Static Pro Engineering, we provide comprehensive Tekla Structures services that cover every stage of the project lifecycle. From early design phases to final fabrication and construction, our team ensures precision and efficiency throughout.

Key features of our comprehensive Tekla services include:

3D Modeling & Visualization – Creating highly detailed and realistic models for improved understanding and collaboration.

Structural Analysis Integration – Linking Tekla with analysis software for load calculations and performance checks.

Fabrication & Shop Drawings – Generating precise drawings, assembly instructions, and cutting lists directly from the model.

Clash Detection & Coordination – Identifying potential conflicts between different disciplines (mechanical, electrical, structural) before construction.

Construction Sequencing & Simulation – Visualizing the build process to optimize schedules and resource allocation.

Data Management & Revision Control – Keeping all stakeholders aligned with up-to-date models and version control.

01

Planning & Conceptualization

How We Start

The planning and conceptualization stage is the foundation of every Tekla-based project. At Static Pro Engineering, we begin by working closely with clients to understand project scope, structural requirements, and site conditions.

This stage includes:

Developing preliminary 3D conceptual models.

Conducting feasibility studies to ensure cost-effectiveness.

Defining project standards, templates, and workflows for Tekla.

Evaluating integration needs with other design and analysis software.

Preparing project schedules and resource plans based on Tekla’s modeling outputs.

02

Detailed Design & Delivery

How We Execute

After the conceptual stage, we move into the detailed design and delivery phase, where Tekla Structures’ full capabilities are utilized.

This phase involves:

Developing highly detailed constructible models with all connections, reinforcements, and fabrication details.

Generating 2D drawings, 3D models, and fabrication data directly from Tekla.

Performing clash detection and structural integrity checks.

Coordinating with fabrication shops for CNC data and material orders.

Providing construction sequencing models for efficient project execution.

Ensuring quality control and compliance with international standards.

What Our Clients Say:

“Our commitment to quality and precision has earned the trust of clients across industries. Here’s what they say about working with us.”