Safe, Efficient, and Tailored to Your Needs

FEA & CFD Analysis

At Static Pro Engineering, we provide advanced Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) services to solve complex engineering challenges. These cutting-edge simulation techniques allow us to test, validate, and optimize designs under real-world operating conditions—before physical prototypes are built.

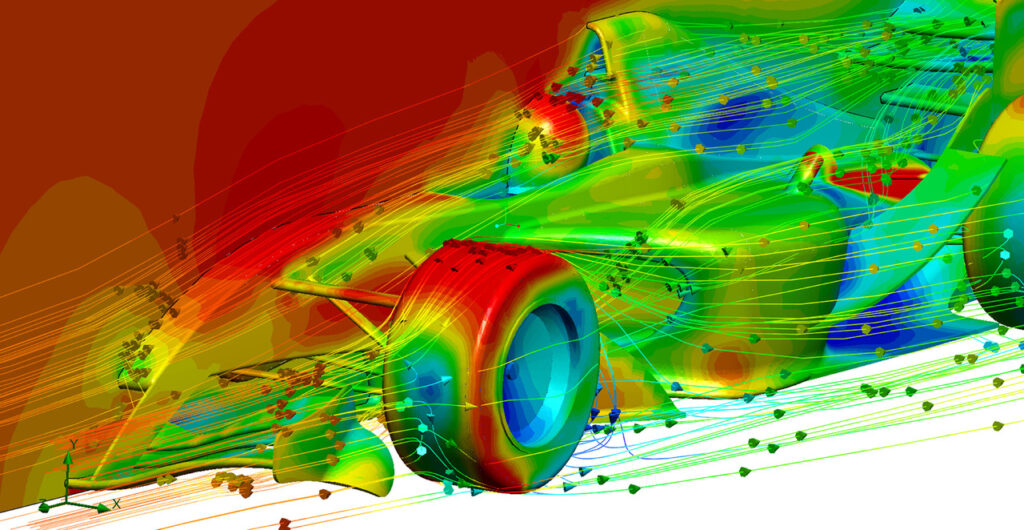

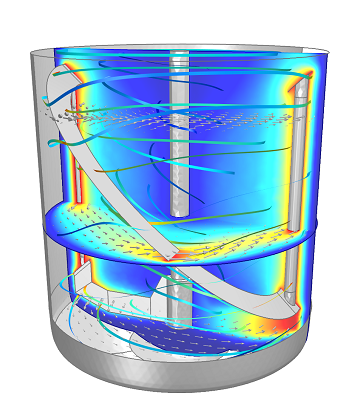

With FEA, we analyze how structures, components, and materials behave under various loads, stresses, and environmental factors. CFD, on the other hand, focuses on fluid flow, heat transfer, and aerodynamics, ensuring that systems operate efficiently and safely. Together, these tools help reduce costs, minimize risks, and accelerate project timelines.

What is FEA & CFD Analysis?

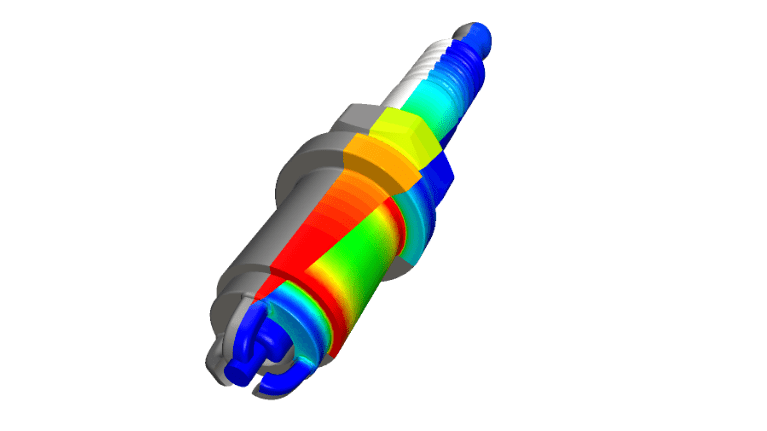

Finite Element Analysis (FEA) is a computational technique used to predict how a structure or component responds to external forces, vibration, heat, and other physical effects. It divides a model into small elements and solves equations to simulate real-world performance. Typical applications include stress analysis, fatigue prediction, thermal expansion, and impact resistance.

Computational Fluid Dynamics (CFD) is a branch of fluid mechanics that uses numerical methods to analyze fluid flow, heat transfer, and turbulence. It helps engineers understand how gases and liquids behave inside and around structures. Applications include aerodynamics, HVAC systems, combustion analysis, and cooling system optimization.

Together, FEA and CFD provide a complete picture of product performance, allowing engineers to detect weaknesses, improve efficiency, and ensure compliance with industry standards before moving to fabrication or construction. At Static Pro Engineering, we use these tools to deliver reliable and cost-effective solutions.

Comprehensive FEA & CFD Analysis

Our comprehensive FEA and CFD services cover the entire spectrum of engineering simulation, from initial modeling to final validation. At Static Pro Engineering, we combine advanced tools with expert knowledge to deliver reliable and actionable results that enhance both design accuracy and overall performance.

The process begins with the development of precise 3D models that replicate real-world geometries and material behaviors. These models are then subjected to various load cases, pressure conditions, thermal effects, and flow environments, enabling our engineers to evaluate how the system or component will perform under actual working conditions. Every simulation is carried out with a focus on accuracy and consistency, ensuring that results can be confidently used in decision-making.

Services Include:

At Static Pro Engineering, our FEA & CFD services are designed to support industries with end-to-end simulation expertise. Our services include:

Structural Analysis & Design Validation

Stress, Vibration & Fatigue Testing

Thermal & Heat Transfer Simulations

Aerodynamics & Fluid Flow Optimization

Combustion & Multiphase Flow Studies

Failure Analysis & Risk Mitigation

Optimization for Efficiency & Sustainability

01

Planning & Conceptualization

How We Start

“At Static Pro Engineering, we follow a structured workflow to ensure every pressure vessel project is delivered efficiently and meets the highest quality standards. Our process begins with a thorough understanding of your operati

The first step in any FEA & CFD project is planning and conceptualization. At Static Pro Engineering, we begin by defining project objectives, identifying potential challenges, and selecting the most suitable analysis methods.

This stage includes:

Understanding client requirements and performance goals.

Developing a conceptual model of the system or component.

Identifying critical loads, boundary conditions, and operating environments.

Evaluating feasibility in terms of time, resources, and cost.

Preparing a simulation strategy tailored to project needs.

nal requirements and project goals, so that every design is tailored to your needs.

02

Detailed Design & Delivery

How We Execute

Once planning is complete, we move to the detailed design and delivery stage, where advanced simulations are carried out using industry-standard tools.

This stage involves:

Creating detailed 3D models for simulation.

Running multiple FEA & CFD scenarios to capture all operating conditions.

Performing clash checks and failure predictions.

Generating comprehensive reports with visual outputs, stress maps, and flow simulations.

Recommending design modifications and optimization strategies.

Delivering validated models and documentation for client use.

What Our Clients Say:

“Our commitment to quality and precision has earned the trust of clients across industries. Here’s what they say about working with us.”