Safe, Efficient, and Tailored to Your Needs-Static Pro Engineering

Static Pro Engineering

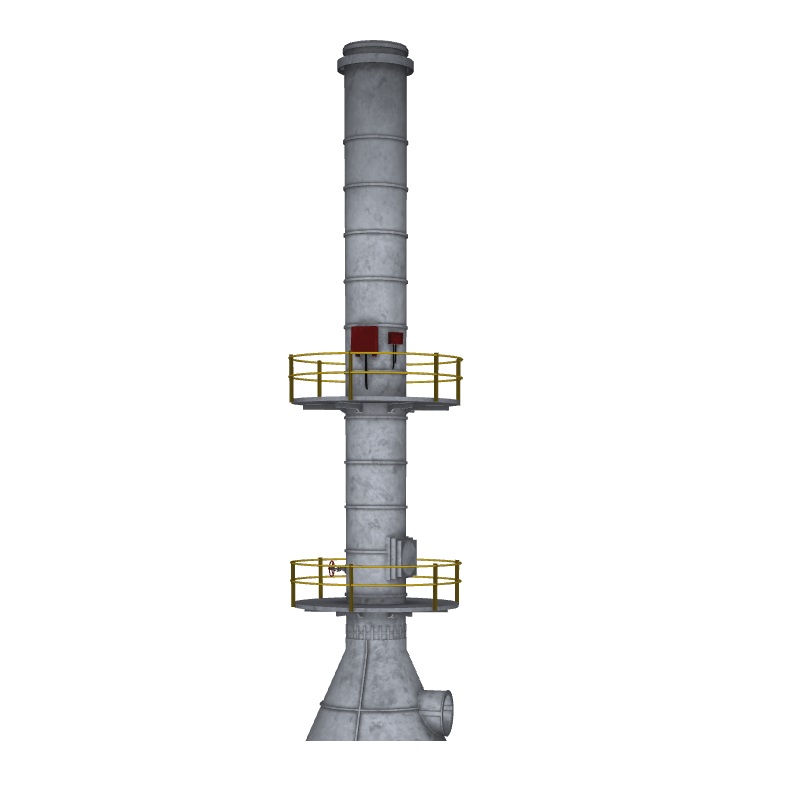

At Static Pro Engineering, we specialize in delivering advanced stack design solutions for industries that rely on safe and efficient exhaust management. Stacks, often called chimneys or flue gas stacks, are critical for releasing combustion gases from boilers, furnaces, and power plants into the atmosphere while ensuring compliance with environmental and safety regulations.

Our focus is not only on structural stability but also on thermal performance, durability, and environmental protection. A well-designed stack ensures that harmful gases are dispersed safely, minimizing their impact on people and the environment. With increasing global emphasis on sustainability and emission control, modern stack design demands high precision, reliable materials, and compliance with international standards.

What is a Stack Design?

Stack design is the engineering process of planning and constructing vertical structures that safely discharge exhaust gases into the atmosphere. The design must consider structural stability, aerodynamics, temperature resistance, corrosion prevention, and environmental compliance.

A properly designed stack ensures adequate dispersion of gases, preventing harmful concentrations at ground level. Factors influencing stack design include:

Height and Diameter – Determines dispersion efficiency and structural integrity.

Operating Temperature & Pressure – Impacts material selection and insulation needs.

Corrosion Resistance – Required to handle acidic and high-moisture flue gases.

Wind & Seismic Loads – External forces that affect structural safety.

Emission Regulations – Ensures compliance with air quality standards.

Comprehensive Stack Design

At Static Pro Engineering, we offer comprehensive stack design services that go beyond structural drawings. Our design process covers every aspect—from environmental studies and emission analysis to material selection and foundation engineering.

Key features of our comprehensive design include:

Structural Stability – Using advanced modeling to ensure the stack can withstand wind loads, seismic forces, and thermal stresses.

Thermal Analysis – Designing insulation and refractory linings to handle extreme exhaust temperatures.

Corrosion Protection – Applying coatings, claddings, or selecting advanced alloys for long-term durability.

Emission Control – Integrating monitoring systems, flue gas treatment, and dispersion analysis to comply with environmental laws.

Safety & Accessibility – Designing ladders, platforms, and inspection points for safe maintenance.

Services Include:

Static Pro Engineering offers a wide range of services for stack design projects, ensuring clients receive complete and reliable solutions. Our services include:

Feasibility Studies – Initial evaluations of site conditions, emission requirements, and project scope.

Custom Design Solutions – Tailoring stack designs to client specifications and industrial needs.

Material Selection – Identifying the best materials for thermal resistance, corrosion protection, and durability.

Simulation & Testing – Using advanced tools to predict structural and thermal behavior under real operating conditions.

Fabrication & Construction Support – Partnering with certified workshops and construction teams to ensure high-quality builds.

Installation & Commissioning – Providing technical oversight during setup for reliable performance.

Inspection & Maintenance Services – Long-term support, including upgrades and retrofits to extend service life.

01

Planning & Conceptualization

How We Start

The planning and conceptualization stage lays the foundation for every stack design project. At Static Pro Engineering, we work closely with clients to understand their process requirements, emission levels, environmental conditions, and regulatory obligations.

During this stage, our engineers develop:

Preliminary layouts based on height, diameter, and material requirements.

Dispersion modeling to ensure emissions meet air quality standards.

Structural concepts to handle wind loads, seismic activity, and thermal stresses.

Cost and feasibility studies to provide accurate project planning.

02

Detailed Design & Delivery

How We Execute

After the planning stage, Static Pro Engineering moves into detailed design and delivery, transforming concepts into practical, build-ready solutions.

The detailed design phase includes:

Final engineering drawings with 2D and 3D models.

Structural and thermal calculations.

Selection of linings, coatings, and protective systems.

Safety systems such as lightning protection, monitoring devices, and access points.

Compliance with codes such as ASME, API, AISC, and local regulations.

Detailed Design & Simulation:

Perform stress, load, and thermal analyses

Optimize materials and design for maximum efficiency

Use advanced CAD and simulation tools for precision

Review & Approval:

Collaborate closely with clients to refine the design

Make adjustments to meet specific project requirements

Ensure all designs comply with international standards

What Our Clients Say:

“Our commitment to quality and precision has earned the trust of clients across industries. Here’s what they say about working with us.”